The egg tray making machine is an innovative item of tools created for the production of top notch egg trays, which are vital for product packaging and carrying eggs securely. Egg tray making machines provide to this demand by offering an automatic approach for producing trays that are not only long lasting and light-weight but likewise ecologically pleasant.

The egg tray making process begins with the collection of waste paper or cardboard, which is then shredded and incorporated with water to create a pulp. This pulp is a green alternative to conventional plastic egg trays, which position considerable disposal obstacles and add to environmental contamination. The pulp undertakes a refining procedure, ensuring that it achieves the best uniformity for molding. As soon as prepared, the pulp is fed right into the egg tray making machine, where it is shaped into trays utilizing mold and mildews that can accommodate different egg sizes. The automated nature of this machinery makes sure that manufacturing is both regular and efficient, making it suitable for organizations looking for to scale their operations.

One of the key advantages of buying an egg tray making machine is the considerable expense savings it offers. Typical egg product packaging methods typically entail sourcing and acquiring pre-made plastic trays, which can be subject and costly to market changes. On the other hand, producing trays in-house permits business to manage their manufacturing expenses better, as they can source resources locally at a lower cost. Additionally, the capability to recycle waste products not only reduces the price of basic materials yet also placements services as environmentally liable entities, appealing to a growing consumer base that prioritizes sustainability.

The adaptability of egg tray machines is an additional noteworthy benefit. These machines can be configured to generate various kinds of trays, consisting of those for chicken eggs, quail eggs, and also fruit, relying on the molds utilized. This adaptability makes sure that organizations can accommodate various market requirements, increasing their item offerings and increasing possible revenue streams. As the market advances, business can quickly customize their manufacturing lines to suit brand-new needs without significant capital investment, making it a wise long-lasting investment.

Security is also a substantial factor to consider in the egg industry, as eggs are fragile items prone to damage throughout transport and handling. Well-designed egg trays give the essential security, supporting the eggs and decreasing the risk of breakage.

In addition to the physical advantages of making use of egg trays, there are likewise substantial advertising and marketing benefits. Eco-conscious consumers increasingly look for items that align with their worths, and naturally degradable packaging is a substantial marketing factor. By making use of an egg tray making machine to generate green trays, companies can properly market their products as accountable and sustainable choices, taking advantage of a pattern that reveals no indications of reducing.

The egg tray making machine runs efficiently, commonly calling for only a tiny team to manage the production procedure. This performance results in reduce labor costs, and the machine's automated attributes reduce human error, making certain premium result with marginal downtime. Modern makers come furnished with advanced modern technology, consisting of PLC (Programmable Logic Controller) systems, which offer individuals real-time tracking of manufacturing metrics, hence enhancing operational effectiveness. This state-of-the-art remedy not just streamlines the manufacturing process but likewise dramatically lowers the demand for manual labor, creating more opportunities for companies to purchase their workforce in various other locations.

Another critical component contributing to the popularity of egg tray machines is the capacity for modification. This customization can consist of modifications in production ability, rate, and also the thickness of the trays produced.

The international need for eggs proceeds to increase, driven by a boost in consumption in emerging markets and changing nutritional preferences worldwide. Investing in an egg tray making machine currently enables services to place themselves advantageously in this progressing market.

Some makers have actually also integrated energy-efficient systems into their egg tray machines, further boosting their sustainability appeal. These machines can run with very little energy usage, efficiently reducing the carbon impact here linked with egg tray manufacturing. This is specifically attracting companies that are striving to fulfill governing needs or aiming to achieve sustainability accreditations. It leads the way for them to market themselves as sector leaders in eco-friendliness, pulling in clients who prioritize these values.

As numerous entrepreneurs and organizations seek to expand their operations, venturing right into egg tray manufacturing uses a rewarding opportunity. The investment in an egg tray making machine is sustained by the premise of using a market with steady need. Offered the low first raw material costs and high return on financial investment, both brand-new start-ups and established business can profit from this possibility. Entering this market straightens with wider fads toward lasting business procedures, where firms are held accountable not just for their earnings but additionally for their social and environmental impact.

Setting up an egg tray making machine requires careful planning and consideration. By selecting to invest in a machine that provides high effectiveness and personalization, services stand much better possibilities of success in the competitive landscape of egg product packaging.

Past manufacturing, recurring upkeep and assistance are critical elements of operating an egg tray making machine. Numerous makers bieten substantial consumer solution and technological assistance, assisting companies in optimizing and repairing possible challenges machine uptime.

Future developments in egg tray making innovation ought to likewise be taken into consideration when assessing prospective financial investments. Technologies in machine layout, such as automated piling systems, are most likely to arise, additionally enhancing manufacturing effectiveness. Expecting these trends can allow businesses to remain ahead of the curve, ensuring that they remain affordable in their offerings. Maintaining an eye on arising technologies, materials, and manufacturing methods will certainly encourage companies to flourish and adapt in an ever-evolving market.

In final thought, the egg tray making machine is a cornerstone of modern-day egg packaging options, offering considerable advantages in terms of efficiency, sustainability, and expense. Ultimately, the combination of an egg tray making machine stands for a strategic investment for services aiming to run responsibly while guaranteeing earnings in the affordable world of egg production and product packaging.

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Shane West Then & Now!

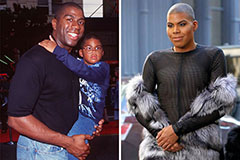

Shane West Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!